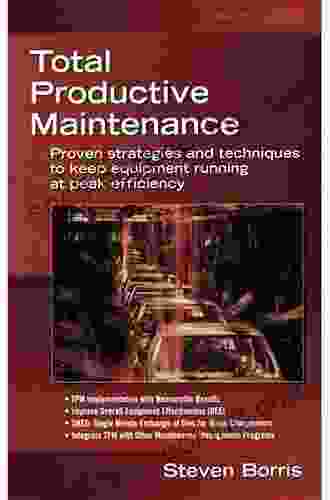

Proven Strategies And Techniques To Keep Equipment Running At Maximum Efficiency

In today's competitive business environment, it is more important than ever to keep your equipment running at maximum efficiency. Downtime can cost you money, productivity, and customers. That's why it's essential to have a sound equipment maintenance strategy in place.

4.7 out of 5

| Language | : | English |

| File size | : | 39685 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 448 pages |

This book will provide you with the strategies and techniques you need to keep your equipment running at peak performance. You'll learn how to:

* Develop a preventive maintenance program * Implement predictive maintenance techniques * Use reliability engineering to improve equipment uptime * Manage spare parts inventory * Train your maintenance team

Chapter 1: Preventive Maintenance

Preventive maintenance is a key part of any equipment maintenance strategy. It involves定期检查维护设备,以防止故障发生。这可以帮助您避免代价高昂的意外停机,并延长设备的使用寿命。

There are many different types of preventive maintenance tasks, but some of the most common include:

* Lubrication * Cleaning * Inspection * Adjustment * Testing

The frequency of preventive maintenance tasks will vary depending on the type of equipment and the operating environment. However, it is generally recommended to perform preventive maintenance tasks at least once per year.

Chapter 2: Predictive Maintenance

Predictive maintenance is a more advanced form of equipment maintenance that uses data to predict when equipment is likely to fail. This allows you to take proactive steps to prevent the failure from occurring.

There are many different predictive maintenance techniques, but some of the most common include:

* Vibration analysis * Oil analysis * Thermography * Ultrasonic testing

Predictive maintenance can be a very effective way to prevent equipment failures and improve uptime. However, it is important to note that predictive maintenance is not a replacement for preventive maintenance. Rather, it is a complementary strategy that can be used to further improve equipment reliability.

Chapter 3: Reliability Engineering

Reliability engineering is a discipline that uses engineering principles to improve the reliability of equipment. Reliability engineers use a variety of techniques to identify and mitigate potential failure modes.

Some of the most common reliability engineering techniques include:

* Failure mode and effects analysis (FMEA) * Fault tree analysis (FTA) * Reliability block diagrams (RBDs)

Reliability engineering can be a valuable tool for improving equipment uptime and reducing maintenance costs. However, it is important to note that reliability engineering is a complex discipline that requires specialized training and experience.

Chapter 4: Spare Parts Inventory Management

Spare parts inventory management is an important part of any equipment maintenance strategy. It involves managing the inventory of spare parts so that you have the right parts on hand when you need them.

There are many different spare parts inventory management strategies, but some of the most common include:

* Safety stock * Min/max inventory levels * Kanban systems

Spare parts inventory management can be a challenge, but it is essential to have a sound strategy in place to ensure that you have the parts you need when you need them.

Chapter 5: Training Your Maintenance Team

Your maintenance team is a key part of your equipment maintenance strategy. It is important to provide them with the training and support they need to be successful.

There are many different types of maintenance training, but some of the most common include:

* Basic maintenance skills * Advanced maintenance skills * Troubleshooting skills * Predictive maintenance skills

Maintenance training can be a significant investment, but it is an investment that will pay off in the long run. A well-trained maintenance team can help you improve equipment uptime, reduce maintenance costs, and improve safety.

By following the strategies and techniques outlined in this book, you can keep your equipment running at maximum efficiency and avoid the costly consequences of downtime.

4.7 out of 5

| Language | : | English |

| File size | : | 39685 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 448 pages |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Book

Book Novel

Novel Page

Page Chapter

Chapter Text

Text Story

Story Genre

Genre Reader

Reader Library

Library Paperback

Paperback E-book

E-book Magazine

Magazine Newspaper

Newspaper Paragraph

Paragraph Sentence

Sentence Bookmark

Bookmark Shelf

Shelf Glossary

Glossary Bibliography

Bibliography Foreword

Foreword Preface

Preface Synopsis

Synopsis Annotation

Annotation Footnote

Footnote Manuscript

Manuscript Scroll

Scroll Codex

Codex Tome

Tome Bestseller

Bestseller Classics

Classics Library card

Library card Narrative

Narrative Biography

Biography Autobiography

Autobiography Memoir

Memoir Reference

Reference Encyclopedia

Encyclopedia Jane Dunnewold

Jane Dunnewold Jeff Pearlman

Jeff Pearlman Janell Cannon

Janell Cannon Janet Hong

Janet Hong Yogan Baum

Yogan Baum Stan S Katz

Stan S Katz Thomas Roedl

Thomas Roedl Jeff Brooker

Jeff Brooker Jan Steinbright

Jan Steinbright Sydelle Kramer

Sydelle Kramer Karla Oceanak

Karla Oceanak Jane Mcgonigal

Jane Mcgonigal William Bartram

William Bartram Jarl Jensen

Jarl Jensen Pyae Moe Thet War

Pyae Moe Thet War Maida Heatter

Maida Heatter Stefanie Japel

Stefanie Japel Jeff Kane

Jeff Kane S L Macgregor Mathers

S L Macgregor Mathers Victoria Bond

Victoria Bond

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Tyrone PowellDavid Rivers Thriller: Shadow Strike - Unravel the Secrets Behind the Covert...

Tyrone PowellDavid Rivers Thriller: Shadow Strike - Unravel the Secrets Behind the Covert...

Benjamin StoneComplete Guide to Buying Low, Fixing Smart, Adding Value, and Selling or...

Benjamin StoneComplete Guide to Buying Low, Fixing Smart, Adding Value, and Selling or... Chance FosterFollow ·7.2k

Chance FosterFollow ·7.2k Banana YoshimotoFollow ·6k

Banana YoshimotoFollow ·6k Jorge AmadoFollow ·13.6k

Jorge AmadoFollow ·13.6k Colby CoxFollow ·6k

Colby CoxFollow ·6k Reed MitchellFollow ·8.3k

Reed MitchellFollow ·8.3k Hunter MitchellFollow ·16.5k

Hunter MitchellFollow ·16.5k Jerry HayesFollow ·14.2k

Jerry HayesFollow ·14.2k Caleb CarterFollow ·6.6k

Caleb CarterFollow ·6.6k

Carlos Drummond

Carlos DrummondHow Companies Win the Mergers and Acquisitions Game:...

In today's...

Craig Blair

Craig BlairMastering The Delicate Balance Between Power And Peace

In today's ever-evolving world, the interplay...

Wade Cox

Wade CoxUnveiling the Zen of Golf: A Journey to Inner Mastery

: The Harmony of Mind,...

Gerald Bell

Gerald BellDarkness Triumphant: Three of the Catmage Chronicles

Synopsis ...

Henry James

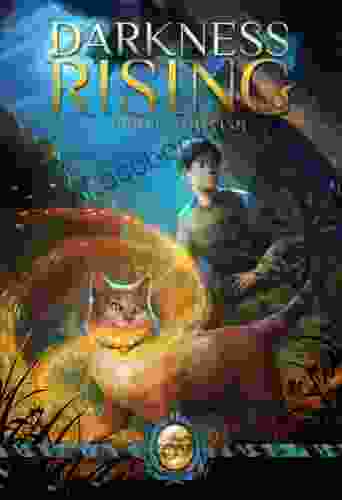

Henry JamesDarkness Rising: One of the Catmage Chronicles

A Captivating Fantasy Adventure...

4.7 out of 5

| Language | : | English |

| File size | : | 39685 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 448 pages |